Clean, dry air for the most sensitive environments

- For food, pharma & semiconductor use

- No oil, no contamination risk

High-speed operation with no lubrication

- No wear, long-term reliability

- Long-term reliability with minimal maintenance

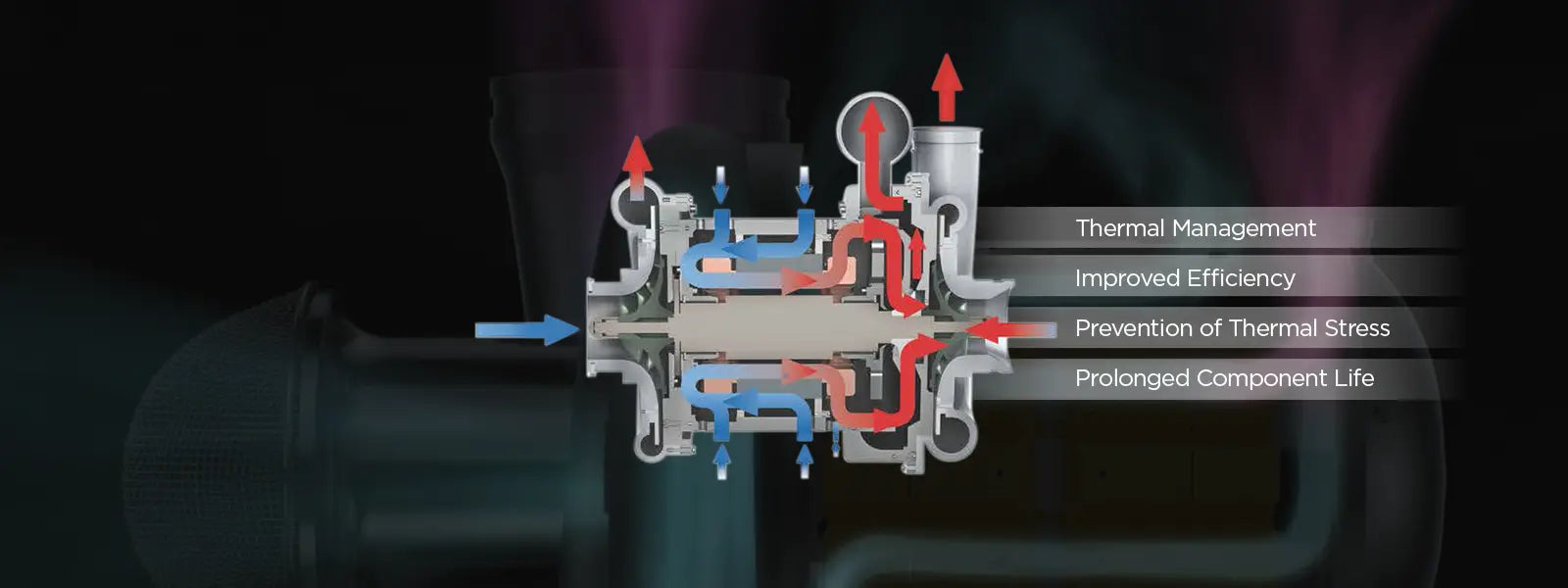

Minimizes energy loss while maintaining output

- Cost-saving and sustainable performance

- Eco-conscious technology for a better planet

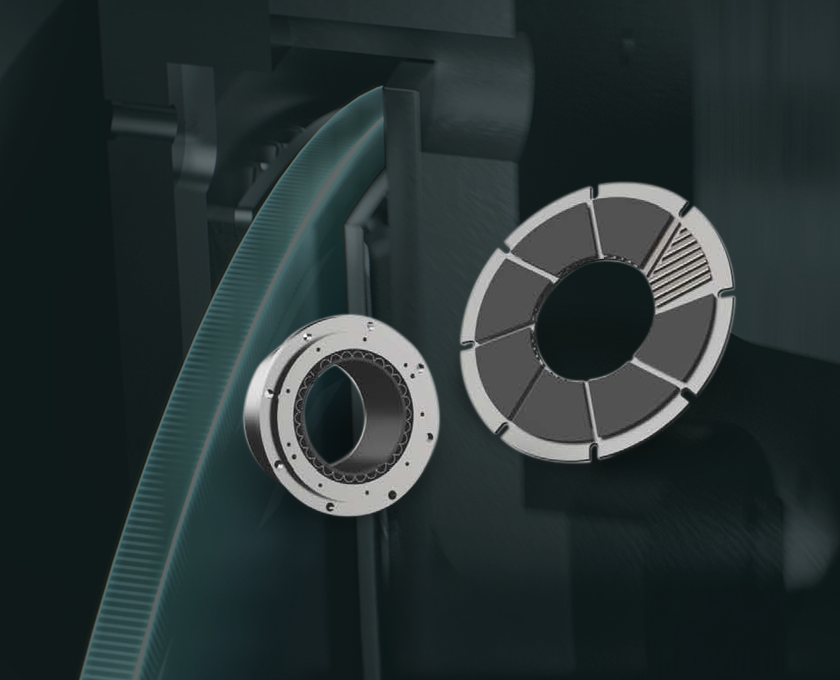

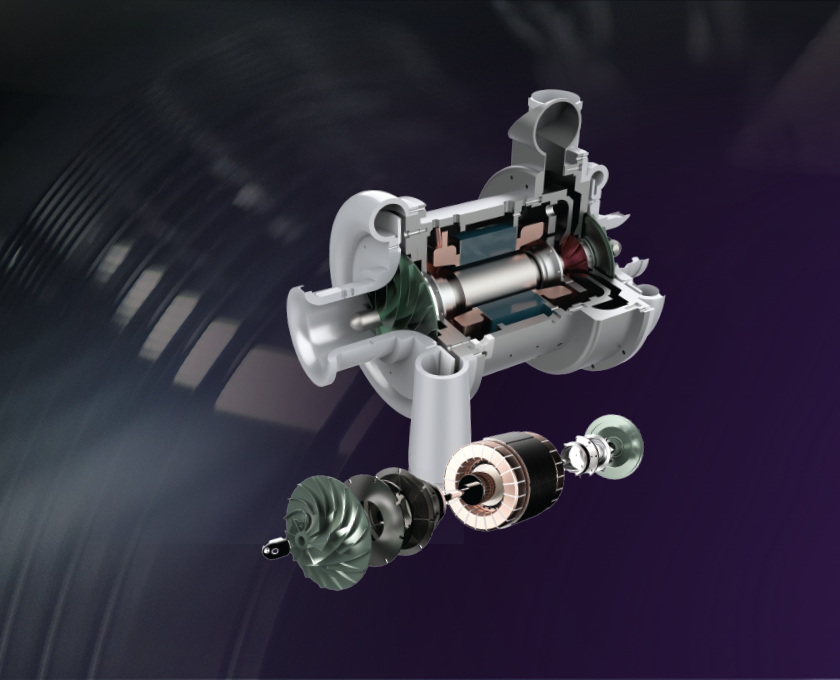

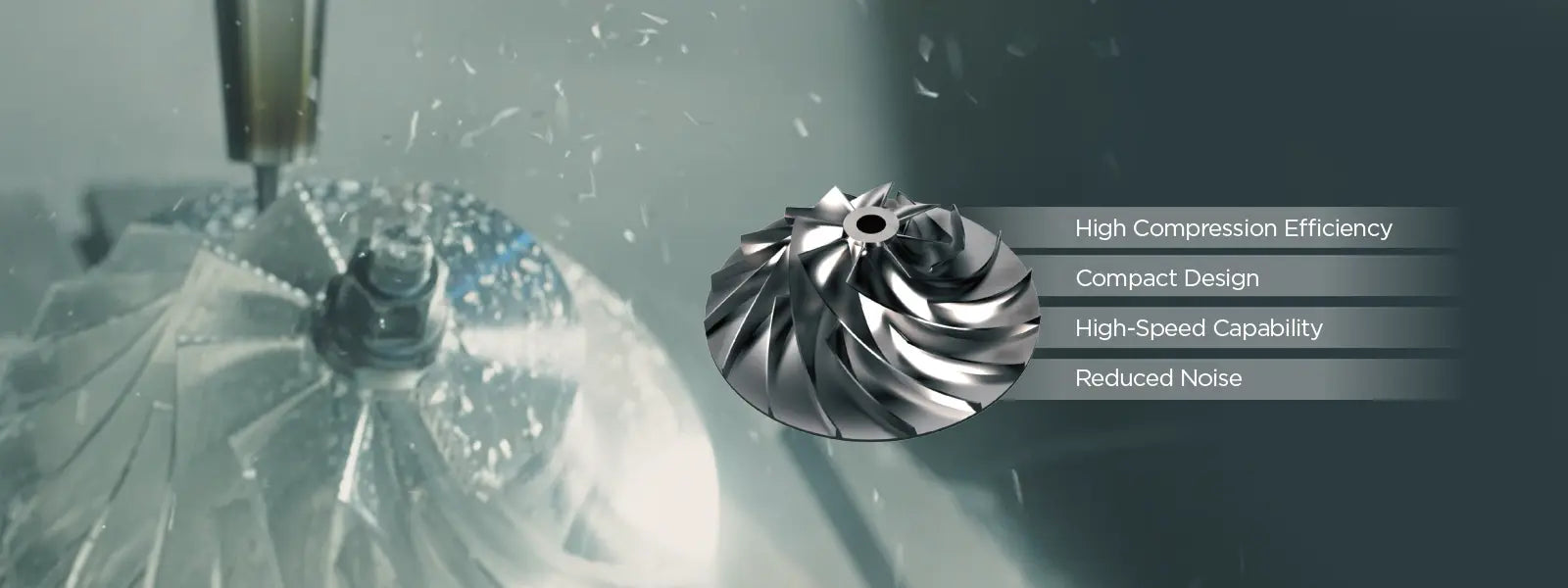

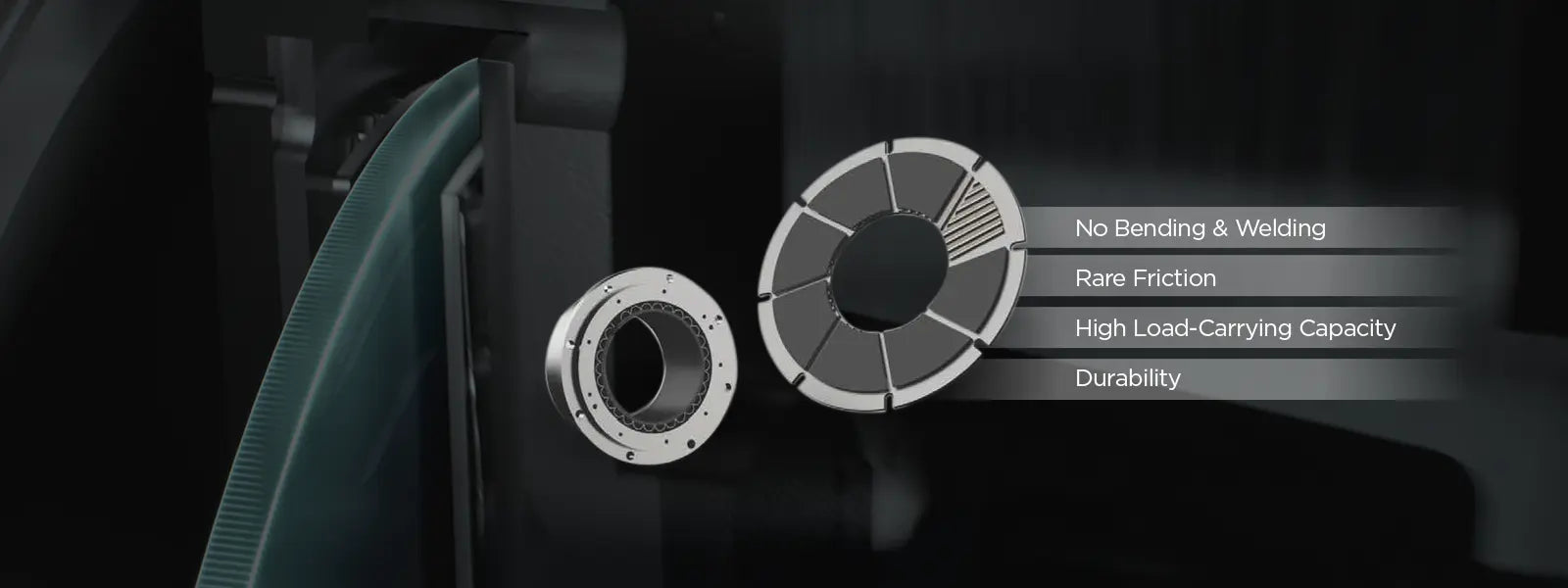

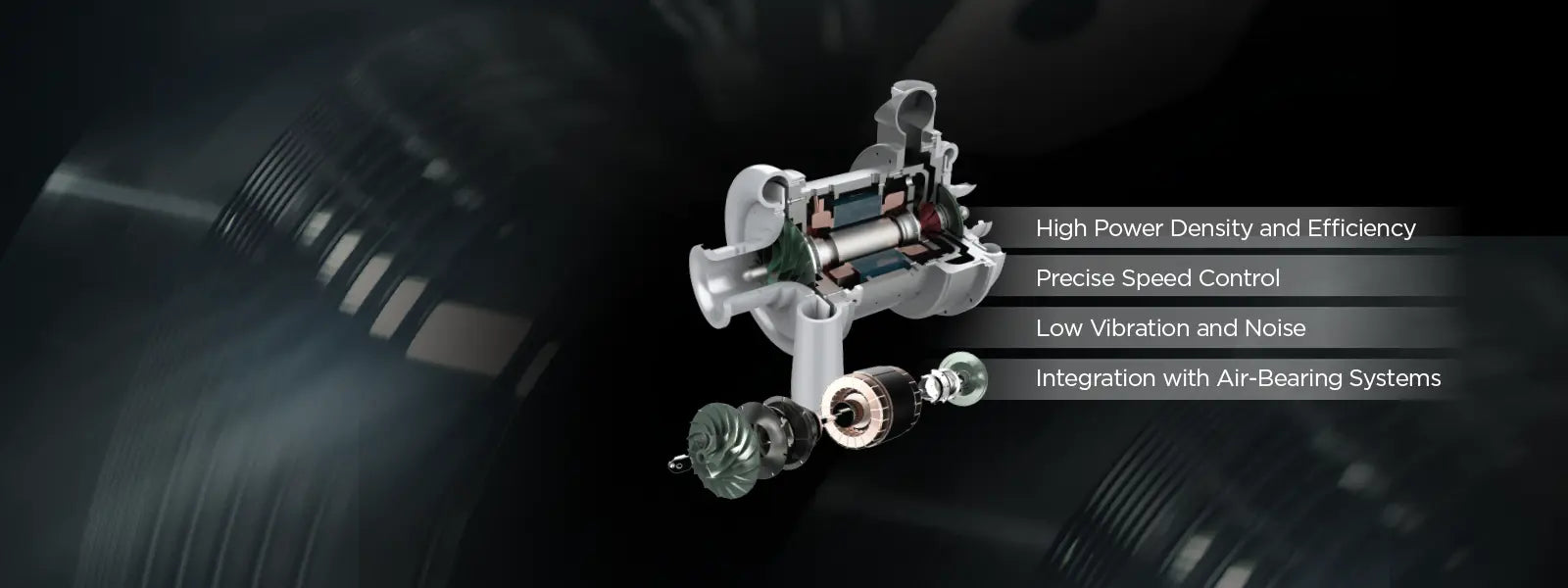

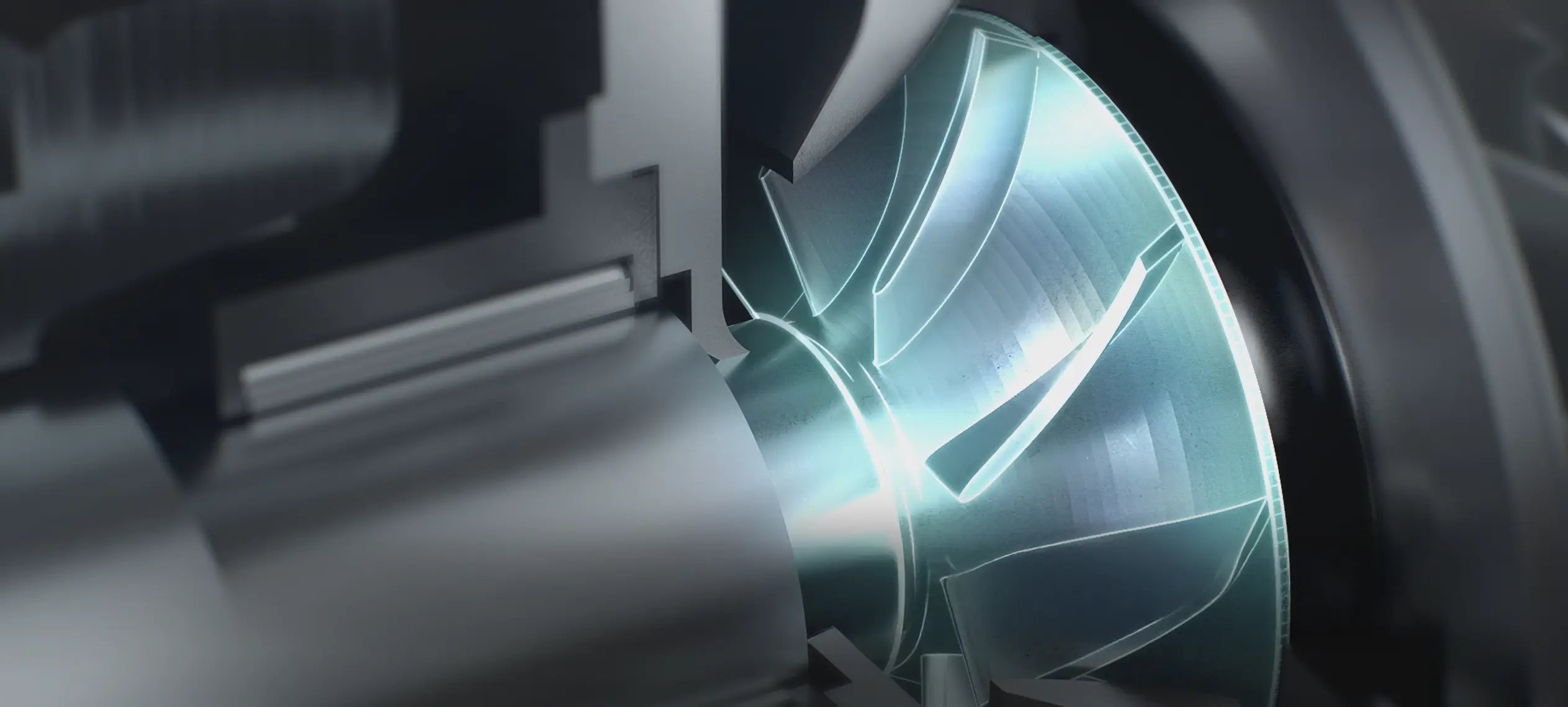

Core Technology

Turbowin’s next-generation turbo technology is designed without compromise. It delivers oil-free, frictionless performance with long-term durability at its core.

We’re here to answer questions

or guide your next step.

Tell us what you need.

we’ll send tailored pricing.

Have a product issue?

Our team’s ready to support.

Easyflex TurboAir Solutions

High-performance systems expertly tailored for lasting industrial excellence.

How Can We Help?

If you have any questions, please fill in this contact form, and our team will reach you back as soon as possible.

News

Easyflex TurboAir at Best Practices EXPO & Conference 2025 Easyflex TurboAir delivers cutting-edge oil-free air compression and aeration systems designed for superior energy efficiency, reliabi...

Easyflex TurboAir at WEFTEC 2025 Easyflex TurboAir delivers advanced oil-free compression and aeration solutions engineered for maximum efficiency, reliability, and modular flexibility. Join us at...

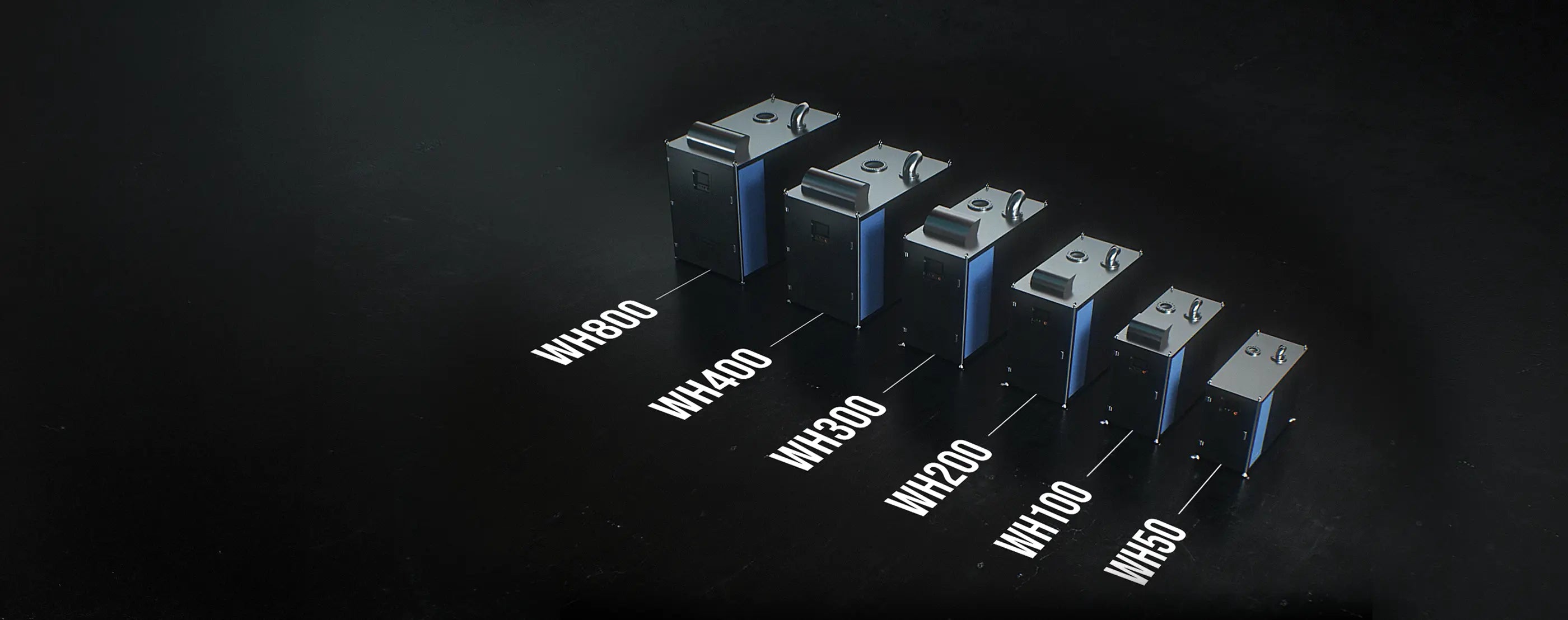

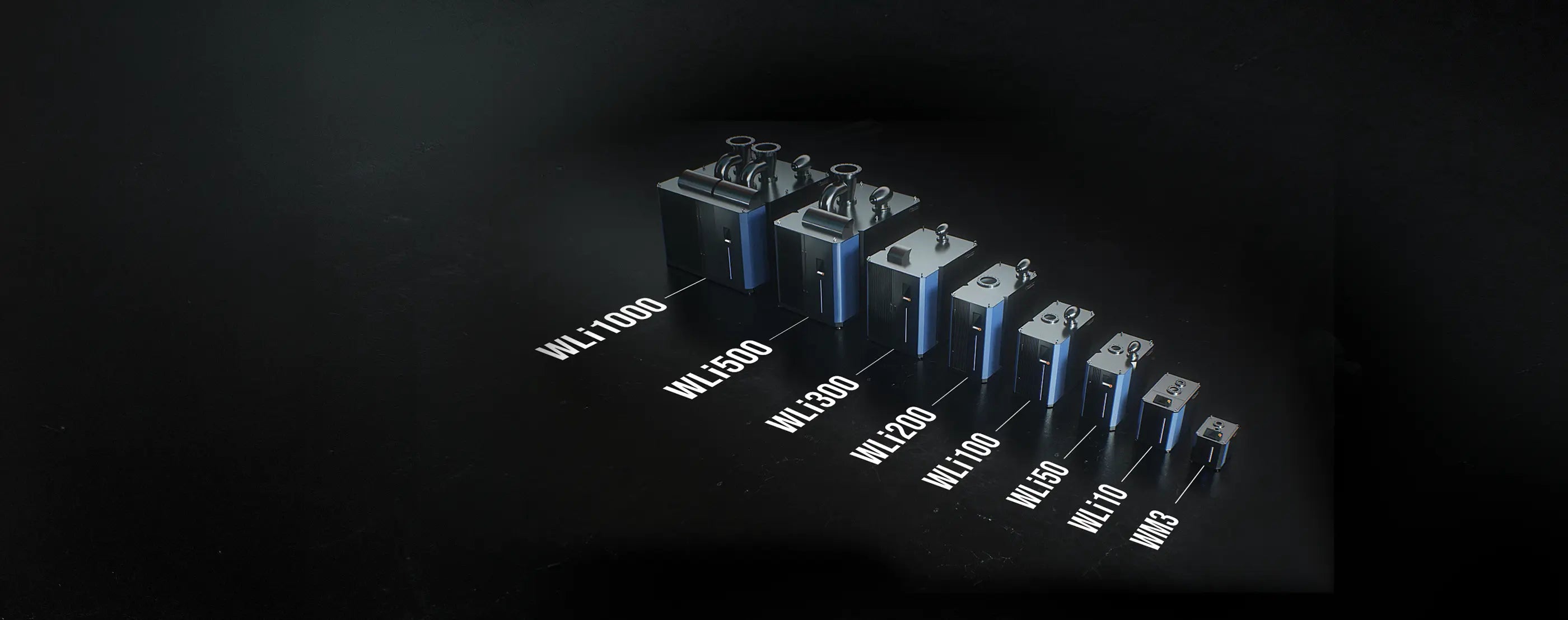

Scroll Through Our Full Lineup

View our full spectrum of products — all together, all here.