FAQs

Quick answers about our products and services.

Product Information

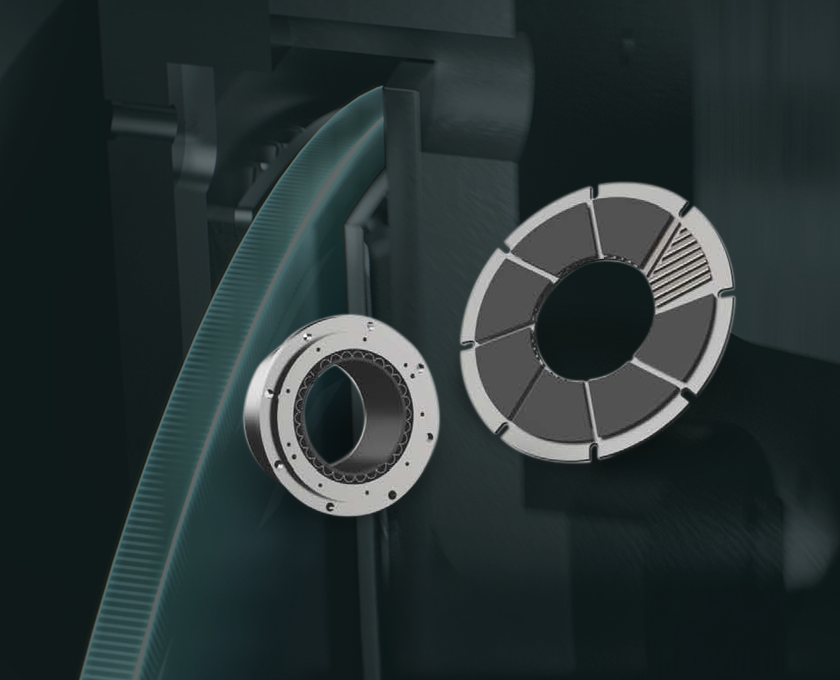

Yes. All WH Series models are 100% oil-free, designed to meet ISO 8573-1 Class 0 standards. (Certification process in progress)

- WL Series – Low-pressure (up to 1.5 bar / ~22 psi), high-flow air for aeration, wastewater, and pneumatic conveying.

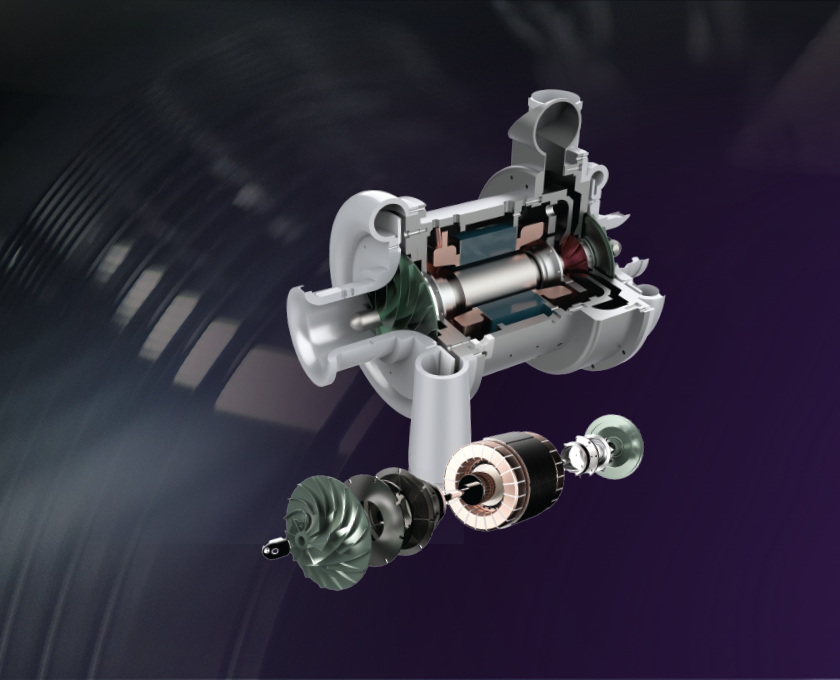

- WH Series – Medium-to-high pressure (2.0–9.0 bar / ~29–130 psi) compressed air for industrial processes.

- WH Series (Compressor): 2.0 to 9.0 bar(g) (~29–130 psi), approx. 10–400+ m³/min (~350–14,100+ cfm)

- WL Series (Blower): up to 1.5 bar(g) (~22 psi), approx. 10–700+ m³/min (~350–24,720+ cfm)

All models are engineered for low-noise operation, typically under 80 dB(A), making them suitable for indoor installation.

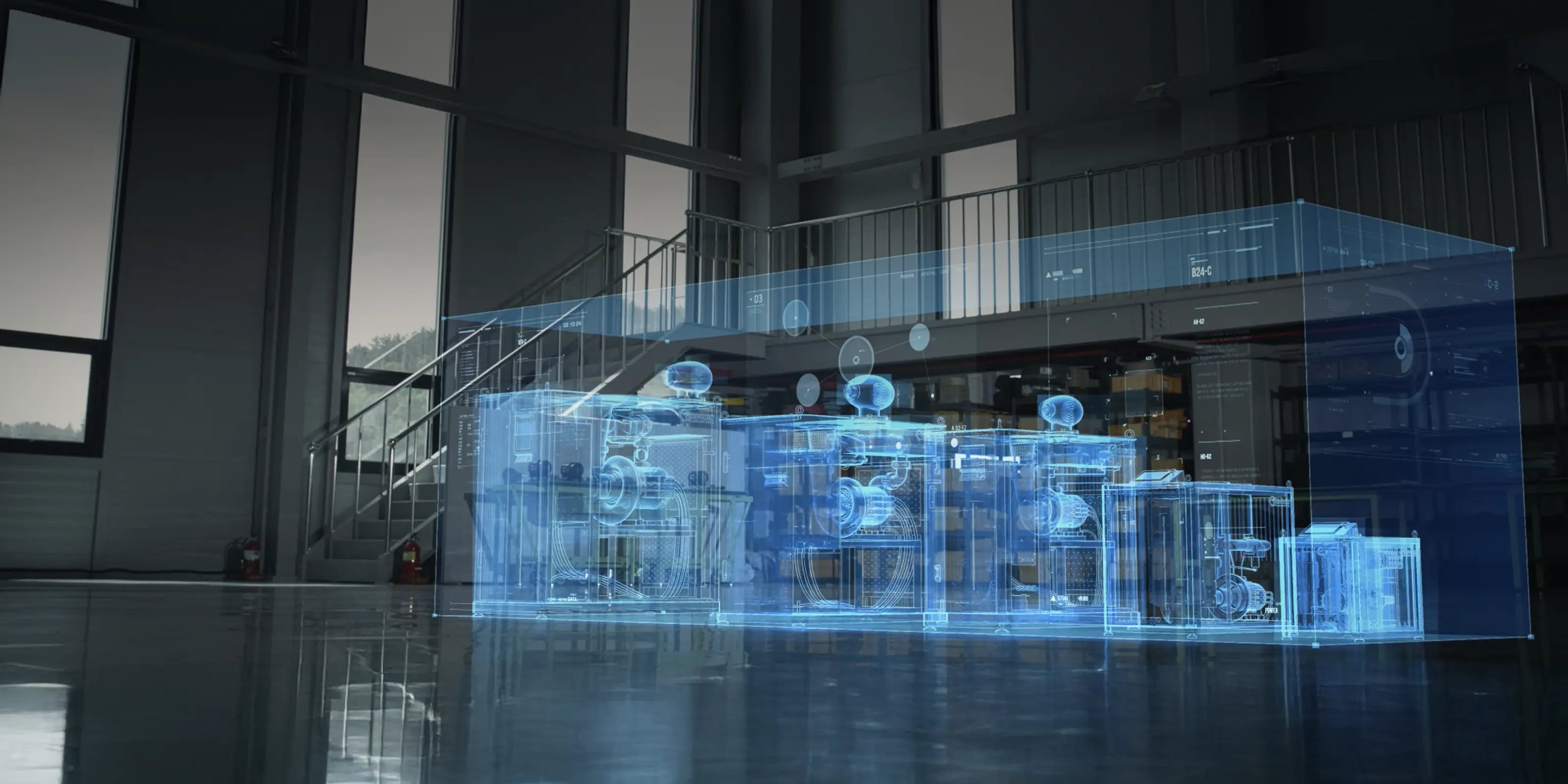

Installation & Customization

Depending on the model and site conditions, you may need a cooling water system (for 4–9 bar models), intake filter, exhaust duct, and appropriate electrical connection equipment.

Yes. We work with qualified installation partners to ensure proper setup, commissioning, and testing.

Yes. We can adjust specifications such as pressure, flow, cooling method (air-cooled or water-cooled), and control options to fit your application.

Maintenance & Support

No oil changes are required. Routine maintenance includes cleaning or replacing intake filters and coolers. Recommended inspection: every 4,000–8,000 operating hours.

Yes. We provide full after-sales support, spare parts supply, and optional maintenance contracts.