▐ Advanced Oil-Free Air Systems for Precision Semiconductor Environments

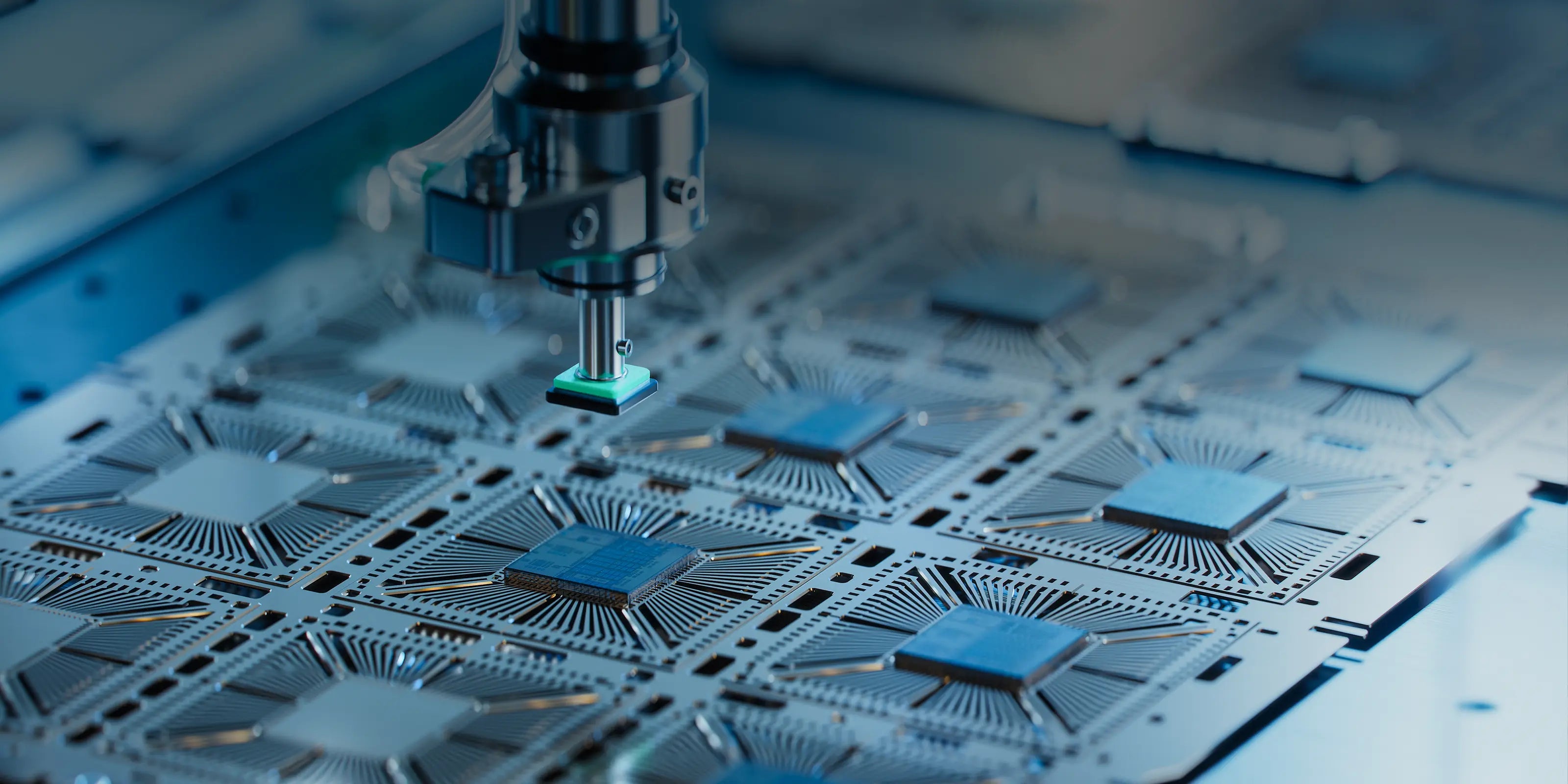

In semiconductor manufacturing, even trace amounts of contamination can impact product yield and reliability.

Compressed air plays a critical role in cleanroom pressurization, wafer handling, and tool operation—making air purity, pressure stability, and uptime essential.

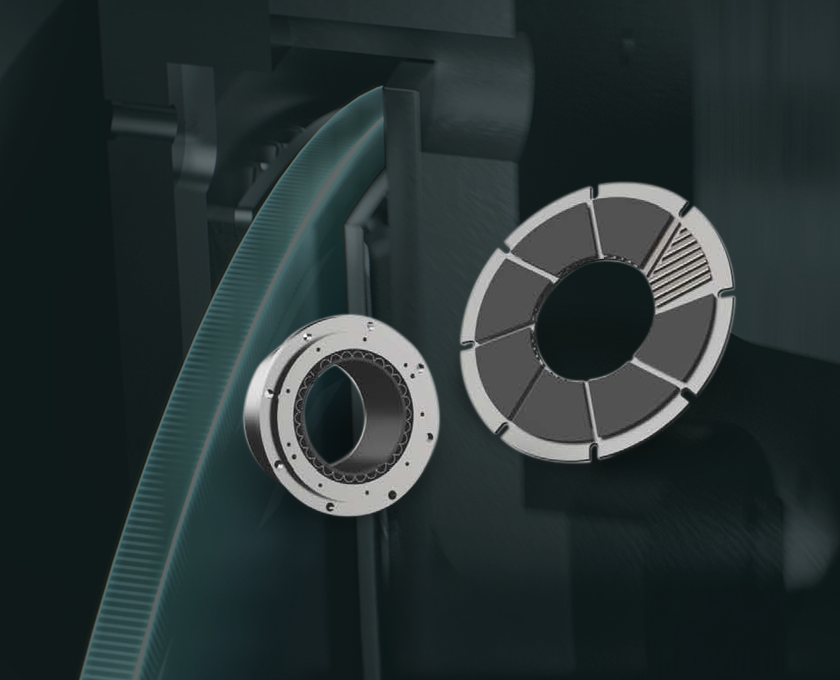

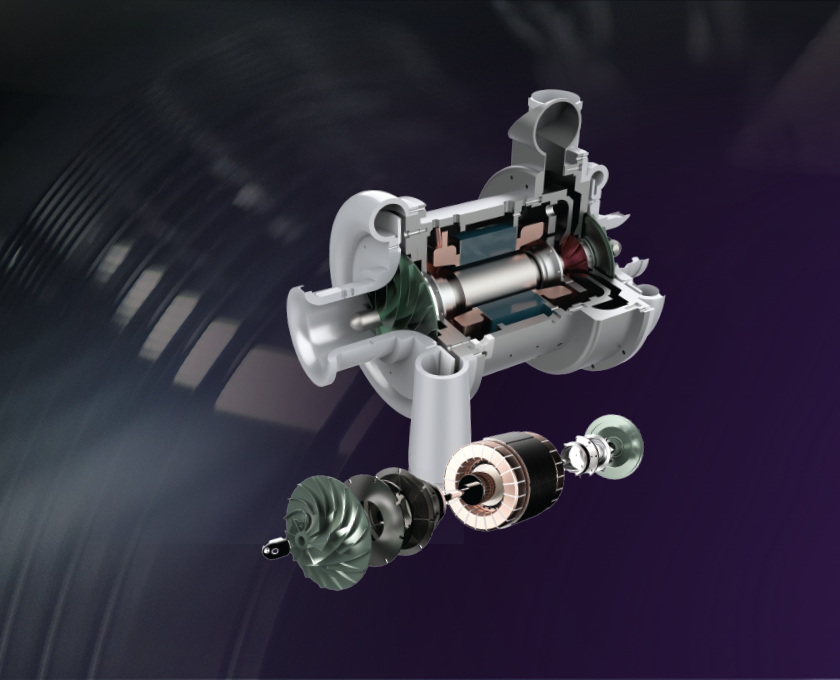

Easyflex TurboAir systems, powered by Turbowin’s advanced oil-free turbo technology, provide ultra-clean, Class 0 certified air with smart control and minimal maintenance—supporting the high-performance demands of today’s fabs and semiconductor facilities.

▐ Applications in Semiconductor Plants

- Cleanroom Air Supply

- Dry Room Pressurization

- Pneumatic Tool Operation

- Process Air for Etching, Deposition, and Packaging

- Vacuum System Support