Turbo Blower

WL Series: High-Efficiency Oil-Free Turbo Blowers

▐ Clean Air. Lower Costs. Proven Industrial Performance.

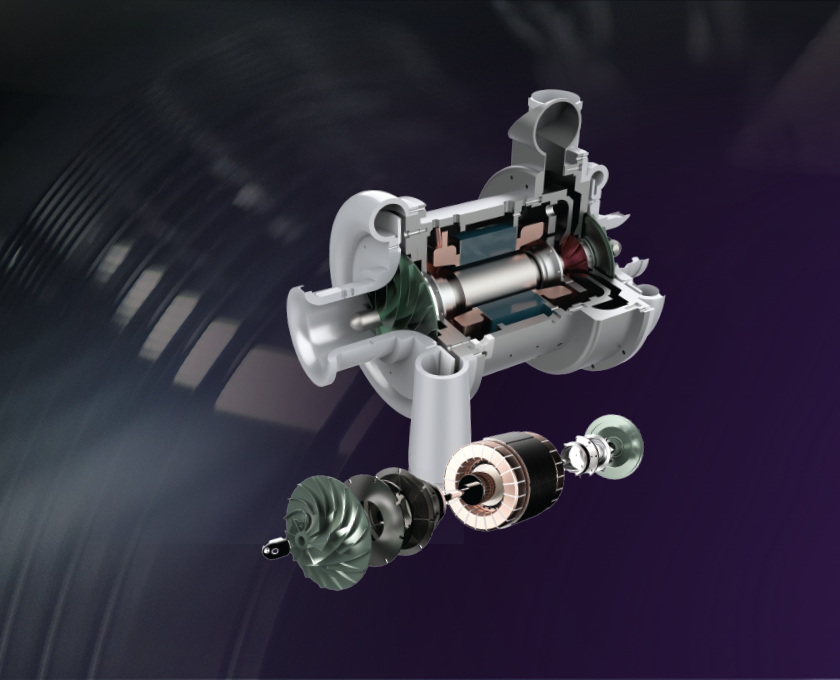

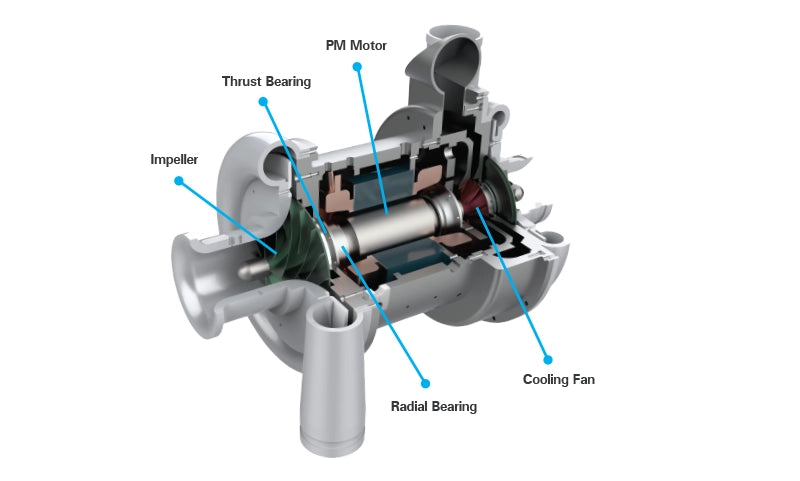

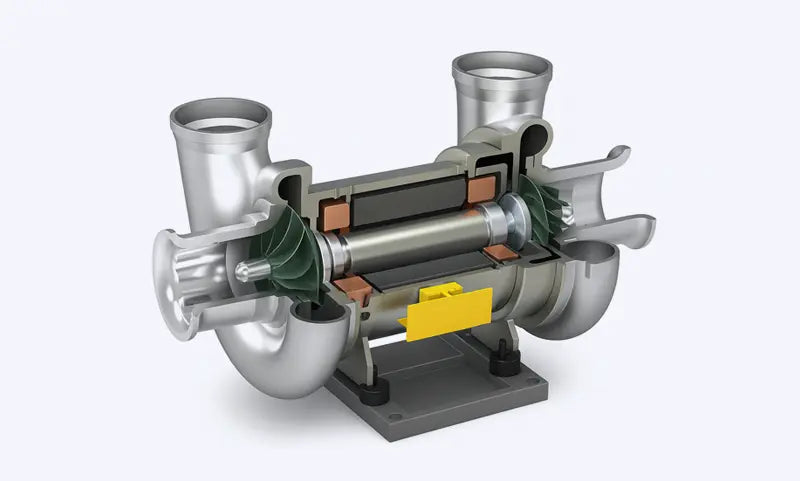

The WL Series from Easyflex TurboAir, powered by Turbowin technology, is a line of centrifugal turbo blowers engineered to deliver 100% oil-free air with exceptional energy efficiency, quiet operation, and long-term durability. Built with airfoil bearing technology and direct-drive motors, the WL Series is the ideal replacement for aging positive displacement and multi-stage blowers—offering up to 40% energy savings and dramatically lower maintenance.

Trusted by industrial and municipal facilities worldwide, the WL Series is now available in the U.S. through Easyflex TurboAir—bringing next-generation air solutions to American infrastructure and manufacturing.

▐ Key Features & Benefits

☑️ 100% Oil-Free, Contamination-Free Air

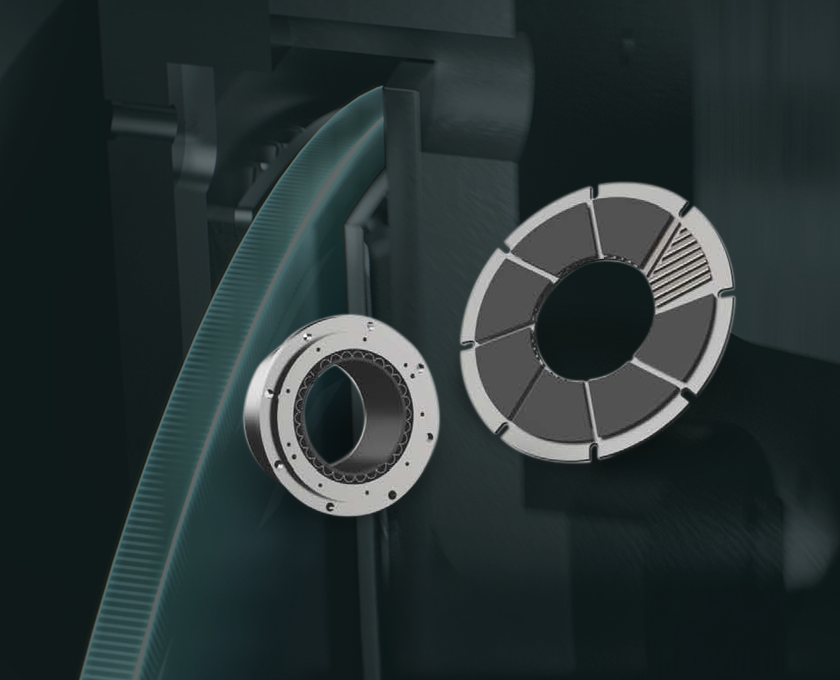

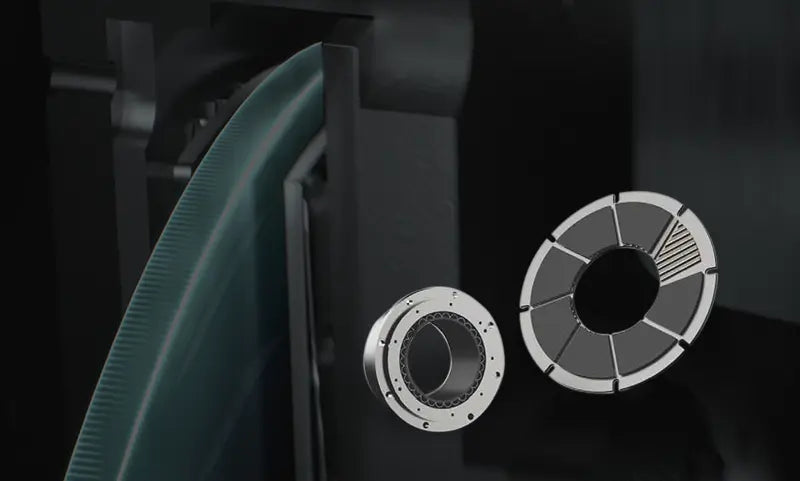

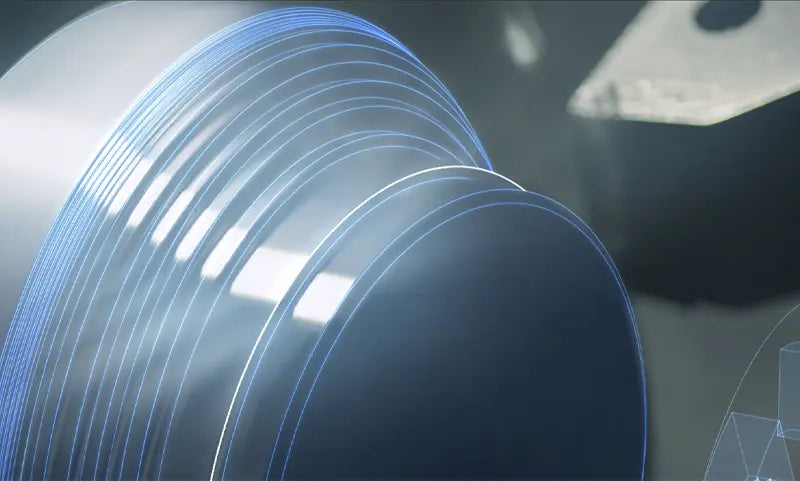

The WL Series uses patented NBW™ airfoil bearings and requires no lubrication—ensuring clean, Class 0 certified air for aeration, conveying, and general plant needs.

☑️ Up to 40% Energy Savings

With high-efficiency impellers and ultra-speed permanent magnet motors, the WL Series consumes significantly less energy than conventional blower systems.

☑️ Quiet & Vibration-Free Operation

Engineered with dynamic balancing and precision manufacturing, the WL Series produceslow noise (<80 dB(A))and virtually no vibration—ideal for indoor or noise-sensitive installations.

☑️ Compact, Direct-Drive Design

The integrated direct-drive system eliminates the need for belts and gears, reducing maintenance while improving efficiency and system uptime.

☑️ Easy Installation & Maintenance

All-in-one compact design with no external cooling or complex foundations required. Minimal moving parts mean lower total cost of ownership over the life of the unit.

☑️ Proven in Global Installations

Over 1,000 units installed across wastewater treatment, electronics, food, and chemical industries—providing dependable, long-term performance in diverse environments.

▐ Ideal Applications

- ✔ Municipal & Industrial Wastewater Treatment

- ✔ Aeration for Activated Sludge Systems (ASP, MBR)

- ✔ Equalization & Mixing Tanks

- ✔ General Plant Air Supply

- ✔ Food & Beverage Processing

- ✔ Electronics & Semiconductor Facilities

- ✔ Pneumatic Conveying Systems

▐ Technical Overview

Explore the core technical attributes that define turbo compressor performance.

5 to 160 m³/min |

|

0.4 to 1.2 bar |

|

10 to 600 HP |

|

< 80 dB(A) |

|

Air-cooled (no external cooling required) |

|

NBW™ Airfoil (oil-free, maintenance-light) |