▐ Clean, Oil-Free Air Solutions for Sanitary Production Environments

In the food, beverage, and brewing industries, air purity is not optional—it’s regulatory. From conveying ingredients to aerating fermenters and powering packaging equipment, compressed air plays a critical role in every stage of production.

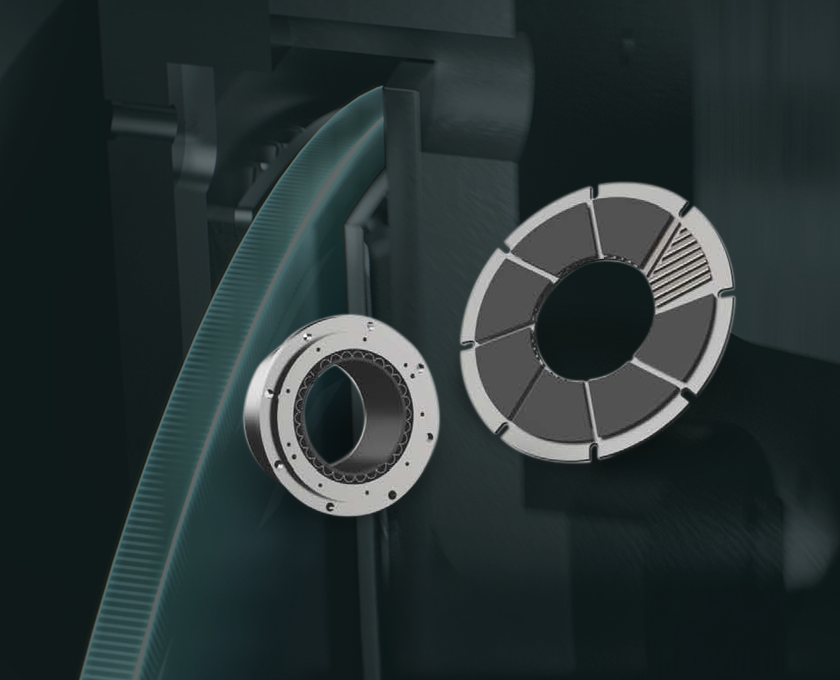

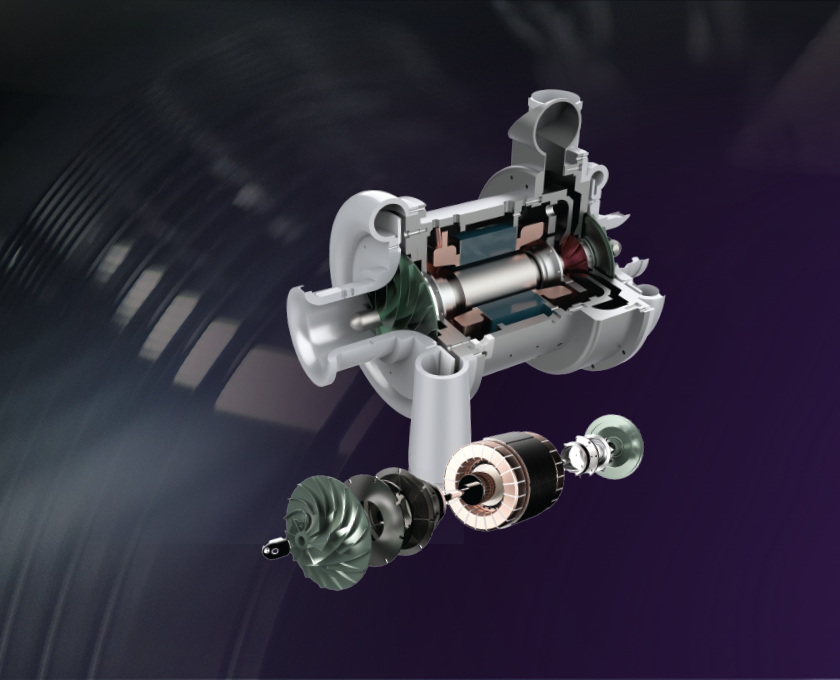

Easyflex TurboAir systems, powered by Turbowin’s advanced oil-free technology, deliver 100% oil-free, ultra-clean air—helping you meet the strictest hygiene standards while improving energy efficiency and system reliability.

Now available across the U.S., Easyflex offers the ideal solution for processors who demand both performance and product safety.

▐ Applications in Food & Beverage Production

- Ingredient Conveying

- Bottle/Can Filling & Packaging

- Fermentation & Brewing Aeration

- Clean-in-Place (CIP) Systems

- Pneumatic Control for Equipment

- Bakery, Snack, and Dairy Processing